HOW TO WORK WITH PNEUMATICS MACHINES

Pneumatic tools offer incredible versatility and efficiency and enables you to effortlessly complete projects. The following pneumatic tool guide provides a quick overview of essential tips for maintaining and operating your tools, so your next pneumatic tool project can blow people’s socks off!

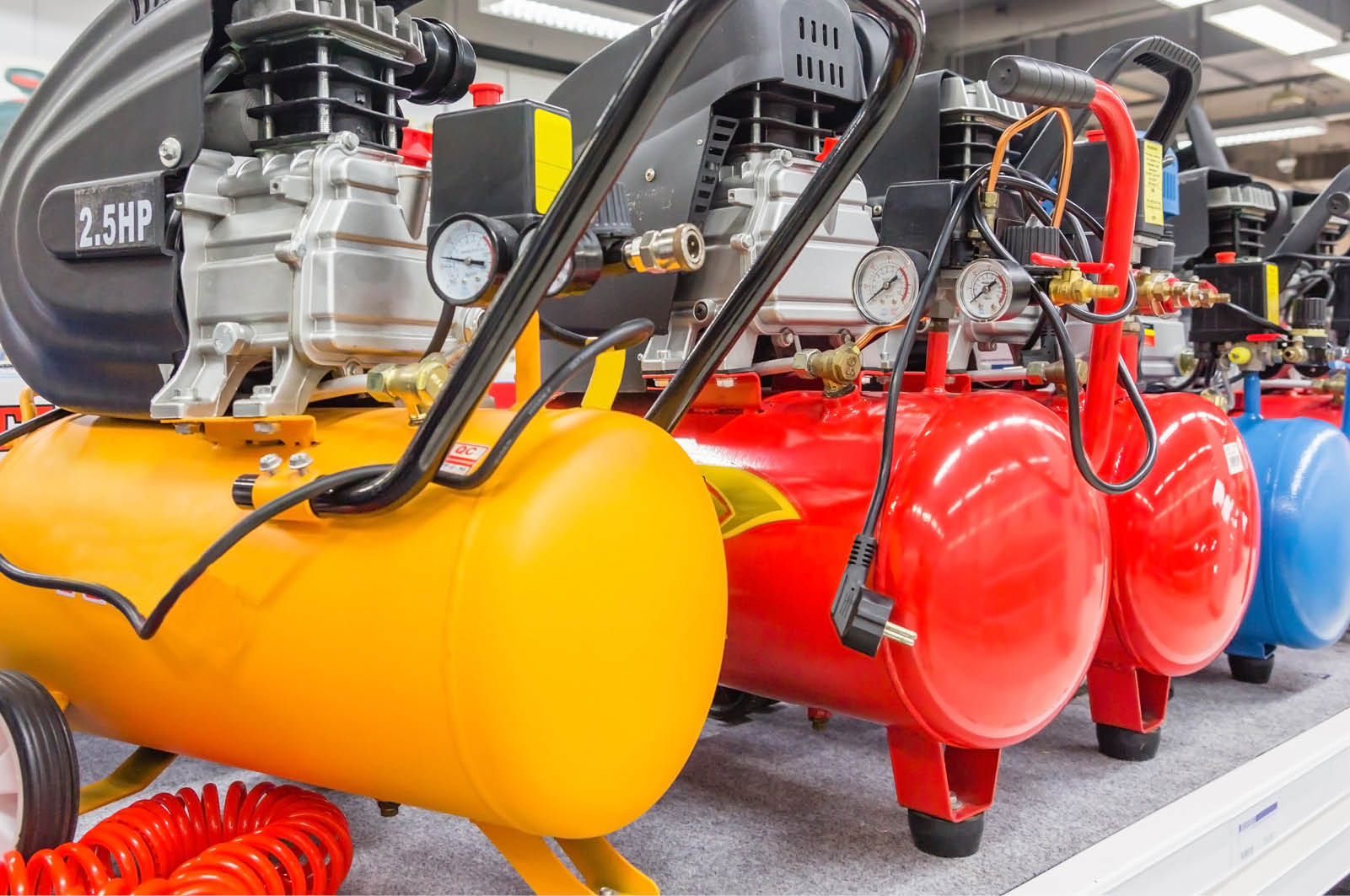

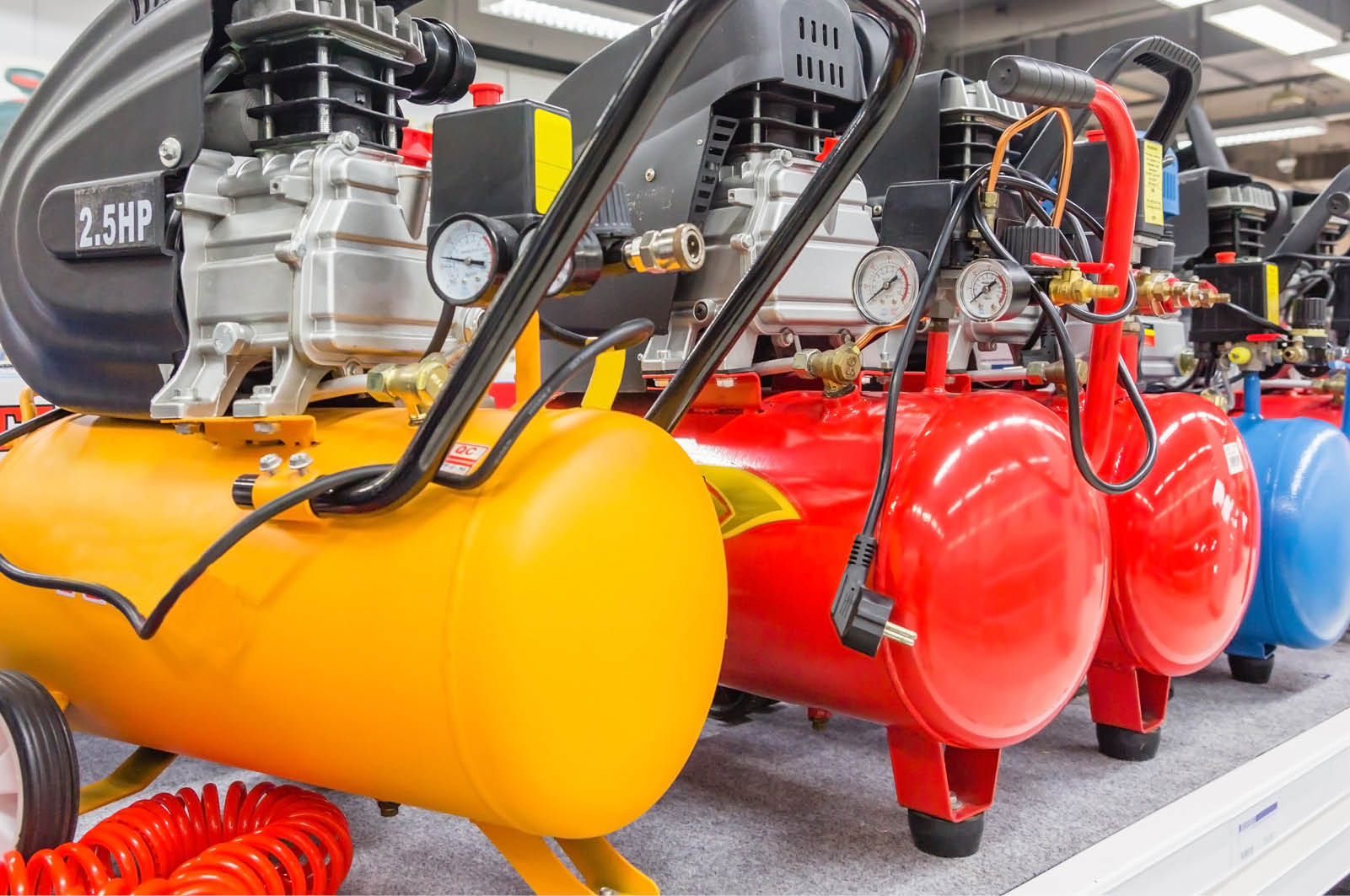

Pneumatic tools rely on high-pressure air from compressors to function. The size of the compressor you require for your project may vary depending on your project needs or level of usage.

Ask any of our friendly Chamberlain consultants to help you in determining what size compressor is ideal for your project needs.

Compressor maintenance

To ensure optimal performance frequently check your compressor’s oil level. Keep an eye on your compressor’s oil gage and ensure your oil levels are always within the red zone.

Frequently check for air leaks on the connector hoses and around the tool connection points, lastly, monthly air filter checks or replacements are recommended to ensure optimal airflow.

Pressure and outlet gauges

All compressors have a pressure control valve that allows the air pressure to be adjusted to the tool and job requirements. Avoid corrosion of your tools by opening the air release valve after use to release any built-up moisture.

Types of tools

Nail guns, spray guns or staple guns are only a few examples of the variety of pneumatic tools that can be connected to your compressor. Remember that different tools require different pressure levels, so always adjust your pressure levels to the level required for your tool.

Pypes and couplers

Only connect and use high-pressure pneumatic pipes that can withstand 3-4 bar of pressure. Additional couplers or tool connectors might need to be purchased to ensure your tools connect to the pneumatic pipe correctly, as not all tools use the same connector couplings. Clamps are recommended to secure each tool and ensure there are no leaks.

Safety

Using/wearing the proper safety equipment is a must when working with high-pressure tools. Safety glasses, ear muffs, and dust masks are essential to protect yourself against flying debris and load machinery noises.